Material, corrosivity, pressure classes

Materials, corrosivity, and pressure classes are critical factors in industrial ventilation systems due to their direct impact on durability, safety, and performance.

Materials

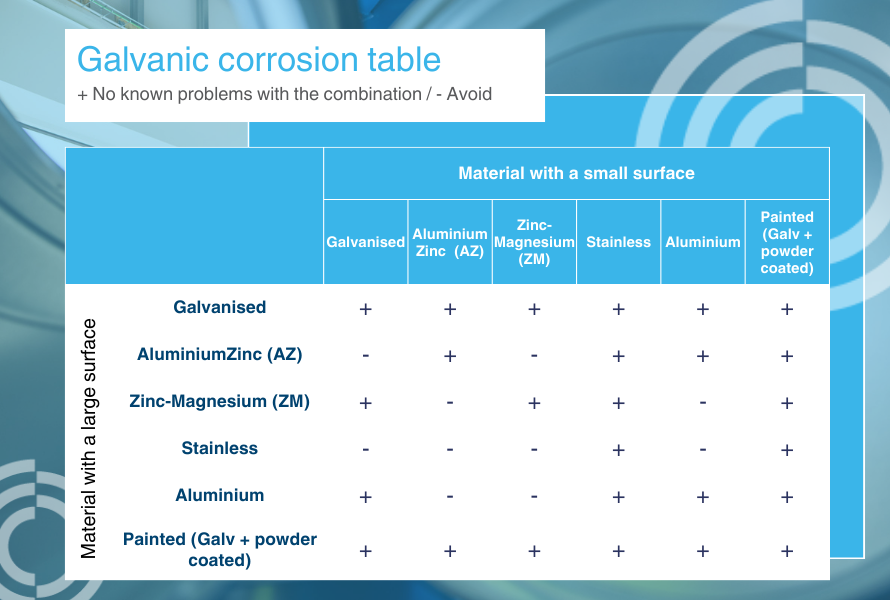

The selection of materials for ventilation components must consider the specific industrial environment. Durable and appropriate materials ensure the system can withstand the physical and chemical conditions it will encounter, thereby extending its lifespan and reducing maintenance costs. For example, stainless steel might be used in environments where chemical resistance is essential, while galvanized steel may be suitable for less corrosive conditions.

- Galvanized Z275

- Recycled galvanized steel GR2 (min. 75% recycled steel)

- Stainless steel EN 1.4301 (AISI 304)

- Stainless steel EN 1.4404 (AISI 316L)

- Aluminium 1050 A

- Zink-Magnesium ZM 310

- and powder coated polyester epoxy.

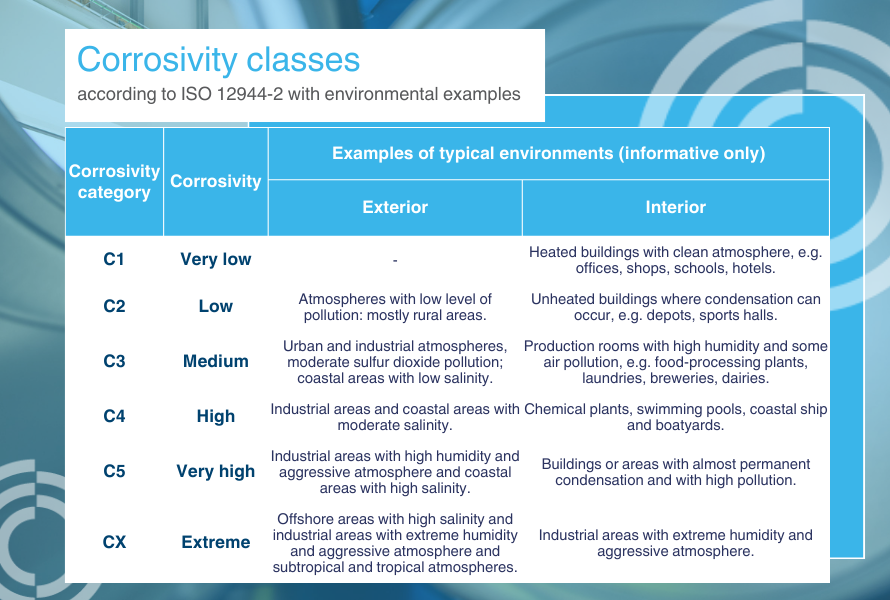

Corrosivity

Industrial environments often contain corrosive substances such as chemicals, fumes, and moisture, which can deteriorate ventilation components over time. Understanding the corrosivity of the environment allows for the selection of materials and protective coatings that resist corrosion, ensuring the reliability and longevity of the ventilation system. This is crucial for maintaining air quality and preventing system failures that could lead to costly downtimes or safety hazards.

Pressure classes

Ventilation systems must be designed to handle varying pressure levels depending on the industrial processes and facility requirements. Different pressure classes indicate the system’s ability to manage high or low-pressure conditions without compromising structural integrity. Correctly specifying pressure classes ensures that the ductwork and components can withstand operational stresses, preventing leaks, and maintaining efficient air flow. This is essential for achieving optimal performance and energy efficiency.